SOLE-CUT – Shape Memory aLloys for stone machining and computer aided Technology

Shape Memory aLloys for stone machining and computer aided Technology

March 14th, 2013

Project descriptions

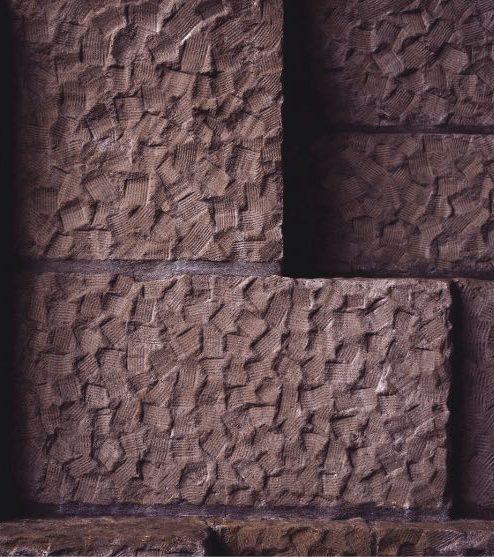

The SOLE-CUT project will provide advanced technical devices (tools and machine tools) and competitive ready-to-market solutions for the stone machining sector. SOLE-CUT will develop shared knowledge, practical know-how and a modern background of simulation methodologies and codes capable of designing and creating new families of high performing stone-cutting-machines. Innovative Shape Memory Alloys and Super-elastic materials will be considered for wire rope (substituting conventional steels) and technical, economic and ecological consistency of materials will be considered, thus producing innovative and green solutions for a more sustainable cutting process. SOLE-CUT proposes an innovative monitoring system, which applies machine vision technology for automatic surface inspection and fault / anomaly prevention in the cutting / carving process. SOLE-CUT groups 4 SMEs, from 3 Regions and 2 countries and integrates scientific and technological expertise with multi-year experience in stone manufacturing.

A detailed description of the project’s activities can be found at solecut.magentalab.it, and www.beamarge.com/solecut/.

Main goals

The project’s activities develop upon the following main objectives:

- study and micro-structural optimisation of SMA materials to create pioneering, feasible, diamond wires;

- investigation of surface treatments for the plasticisation of the SMA materials and the development of more effective solutions for joining diamond beads to the rope;

- in-depth and detailed simulation of the whole cutting process in order to provide scientific support to the real-time monitoring of the process;

- research of high-tech plasticisation methods and avant-garde sintered diamond beads, thanks to the analysis of sophisticated and/or innovative treatments;

- industrialisation and functionality analysis of the diamond wire and the cutting process in order to increase operating capabilities reducing, at the same time, the energetic and environmental impact;

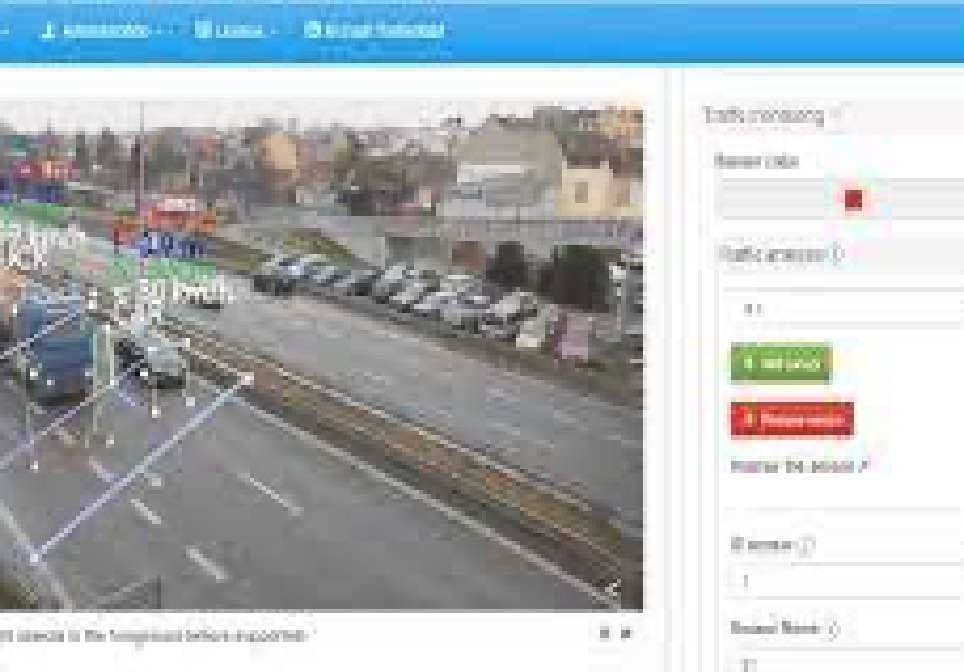

- development of a computer vision-based system for automatic inspection and monitoring of the stone materials and manufacturing process.

- triple experimental phase: validation activities through vision machine system tests, new SMA cutting material tests, entire system test.

Test plant

In Tuscany, the main test plant will be located in Frosini Pietre, and will employ an open-frame gang saw used to cut stones such as the Macigno.

Other related works

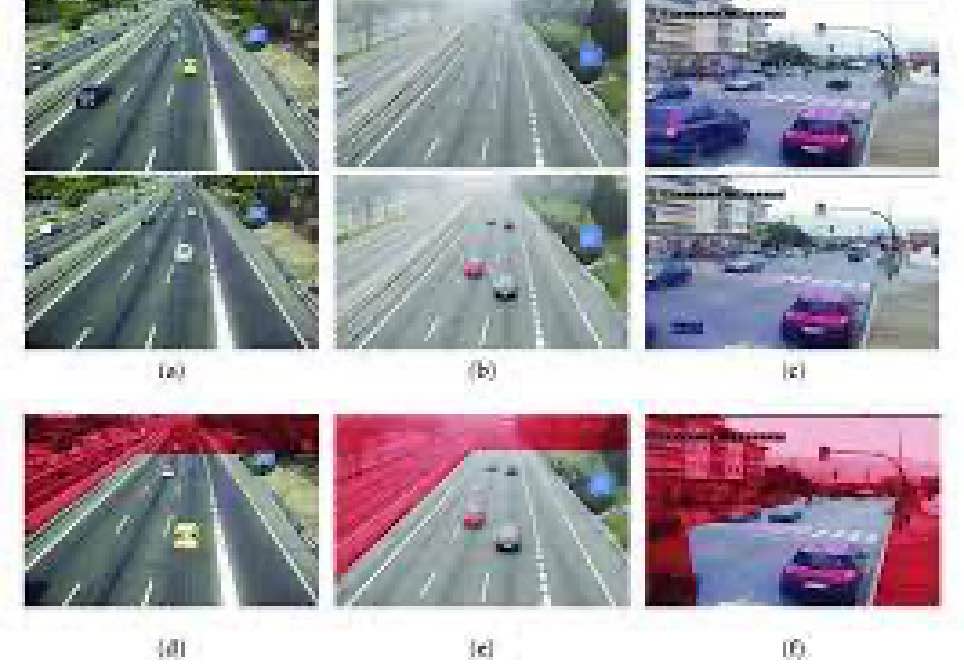

ORUSSI – Optimal Road Surveillance System based on Scalable Video

Piattaforma Integrata per la Gestione delle Operazioni Aeroportuali.